3.3*6.5M Offshore/Mooring/Port/Harbor/Ferry Foam Filled Fenders for

Naval Marinas

Description

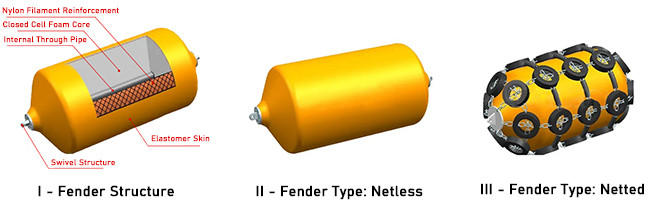

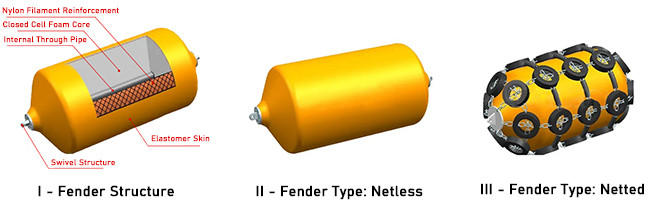

Foam-filled fenders, also known as foam fenders or foam-filled

marine fenders, are a type of fender used in the maritime industry

to provide protection and cushioning between vessels and various

structures. These fenders are constructed using a high-density

closed-cell foam core, which is then encased in a tough, durable

outer skin made of polyurethane or other synthetic materials.

The foam core of these fenders is designed to absorb and distribute

impact energy, reducing the risk of damage to both vessels and

structures during docking, mooring, or ship-to-ship operations.

This innovative design allows foam-filled fenders to provide

superior performance and reliability compared to traditional rubber

fenders.

One of the key advantages of foam-filled fenders is their ability

to resist punctures and maintain their integrity, even when

subjected to harsh environmental conditions, extreme temperatures,

or exposure to oil, chemicals, and UV radiation. This makes them

highly suitable for use in offshore platforms, ports, marinas, and

other demanding marine environments.

Another notable feature of foam-filled fenders is their low

maintenance requirements. Unlike pneumatic fenders that require

regular inflation and monitoring, foam-filled fenders are

self-floating and do not depend on air pressure to maintain their

shape and performance. They are also resistant to damage caused by

abrasion, aging, and corrosion, resulting in a longer lifespan and

reduced maintenance costs.

Foam-filled fenders are available in various sizes, shapes, and

configurations to accommodate different types of vessels and

specific operating conditions. They can be customized to meet

specific requirements and can be easily installed or replaced as

needed.

Overall, foam-filled fenders provide a reliable and cost-effective

solution for vessel protection and safety in the marine industry.

Their superior impact absorption capabilities, durability, and low

maintenance requirements make them a popular choice for a wide

range of applications, from commercial shipping and port operations

to offshore oil and gas platforms, navy vessels, and recreational

boating.

Specifications

| Place of Origin | China |

| Brand Name | DockFender |

| Model Number | DF-3.3*6.5M |

| Product Name | 3.3*6.5M Offshore/Mooring/Port/Harbor/Ferry Foam Filled Fenders for

Naval Marinas |

| Material | Polyurethane, EVA, etc |

| Standard | US Navy, PIANC, ISO9001 |

| Density | 54-70kg/m³ |

| Tensile Strength | ≥414 kN/m³ |

| Diameter | 500mm-4500mm |

| Length | 1000mm-9000mm |

| Shape | Cylindrical |

| Service | OEM or ODM |

| Application | Used for protect the ship and dock |

| Diameter x Length | Energy absorption at 60% comp | Reaction force at 60% comp | Approx. weight |

| (mm) | (kNm) | (kN) | (kg) |

| 300 x 1000 | 3.8 | 54 | 11 |

| 500 x 1000 | 10.6 | 91 | 41 |

| 600 x 1000 | 15.3 | 109 | 49 |

| 600 x 1000 | 18.3 | 131 | 55 |

| 700 x 1500 | 31 | 191 | 85 |

| 750 x 1500 | 36 | 204 | 89 |

| 900 x 1800 | 62 | 294 | 140 |

| 1000 x 1500 | 64 | 272 | 125 |

| 1000 x 2000 | 85 | 363 | 170 |

| 1200 x 2000 | 122 | 436 | 275 |

| 1200 x 2400 | 146 | 523 | 365 |

| 1250 x 2000 | 132 | 454 | 353 |

| 1250 x 2500 | 165 | 567 | 410 |

| 1500 x 3000 | 286 | 817 | 570 |

| 1500 x 4000 | 381 | 1089 | 720 |

| 1700 x 3000 | 367 | 926 | 700 |

| 1700 x 3500 | 428 | 1080 | 780 |

| 1800 x 3000 | 412 | 980 | 850 |

| 1800 x 3600 | 494 | 1176 | 965 |

| 2000 x 3000 | 508 | 1089 | 965 |

| 2000 x 3500 | 593 | 1271 | 1100 |

| 2000 x 4000 | 678 | 1452 | 1220 |

| 2400 x 4000 | 976 | 1743 | 1720 |

| 2400 x 4800 | 1171 | 2091 | 2140 |

| 2500 x 4000 | 1059 | 1815 | 1865 |

| 2500 x 5000 | 1324 | 2269 | 2500 |

| 2500 x 5500 | 1456 | 2496 | 2675 |

| 2700 x 5400 | 1668 | 2647 | 2865 |

| 3000 x 5000 | 1925 | 2750 | 3200 |

| 3000 x 6000 | 2287 | 3268 | 3740 |

| 3300 x 6500 | 2998 | 3894 | 4735 |

| 3600 x 7200 | 3953 | 4706 | 5800 |

| 4000 x 8000 | 4522 | 5809 | 8700 |

| 4200 x 8400 | 6277 | 6405 | 10000 |

| 4500 x 9000 | 7720 | 7353 | 10700 |

Features

1. Impact Absorption: Foam-filled fenders are designed to

effectively absorb and distribute impact energy during

vessel-to-vessel or vessel-to-structure contact. The high-density

closed-cell foam core provides excellent cushioning, reducing the

risk of damage to both vessels and structures.

2. Durability: These fenders are constructed with a tough outer

skin made of polyurethane or other synthetic materials, which

provides superior resistance against punctures, abrasion, aging,

and corrosion. They can withstand harsh environmental conditions,

extreme temperatures, and exposure to oil, chemicals, and UV

radiation.

3. Low Maintenance: Unlike pneumatic fenders that require regular

inflation and monitoring, foam-filled fenders are self-floating and

do not rely on air pressure. This eliminates the need for

maintenance tasks such as inflation checks, resulting in lower

maintenance requirements and costs.

4. Customizability: Foam-filled fenders are available in various

sizes, shapes, and configurations to suit different types of

vessels and specific operating conditions. They can be customized

to meet specific requirements and can be easily installed or

replaced as needed.

5. Longevity: Thanks to their durable construction and resistance

to damage, foam-filled fenders have a longer lifespan compared to

traditional rubber fenders. This translates to cost savings and

reduced downtime caused by frequent replacements.

6. Safety: By providing a reliable buffer between vessels and

structures, foam-filled fenders enhance safety during docking,

mooring, and ship-to-ship operations. They help minimize the risk

of collisions, preventing potential injuries to crew members and

damage to vessels or infrastructure.

7. Versatility: Foam-filled fenders are suitable for a wide range

of applications in the marine industry, including offshore

platforms, ports, marinas, navy vessels, commercial shipping, and

recreational boating. Their versatility makes them a preferred

choice across different sectors.

Applications

1. Port and Harbor Protection: Foam-filled fenders are commonly

used to protect port infrastructure such as piers, docks, and quay

walls. They act as a cushioning barrier between vessels and

structures, absorbing the energy generated from vessel impacts

during docking and mooring.

2. Offshore Operations: Oil and gas platforms, wind farms, and

other offshore structures require protection against vessel

collisions. Foam-filled fenders are installed around these

structures to provide a buffer zone, minimizing the risk of damage

caused by ships or support vessels during operations.

3. Ship-to-Ship Transfers: When transferring cargo or personnel

between two vessels at sea, foam-filled fenders are used to create

a stable and safe transfer platform. By preventing direct contact

between the two ships, these fenders aid in preventing damage and

ensuring the safety of crew members involved in the transfer.

4. Navy and Military Applications: Foam-filled fenders are widely

used in naval operations for vessel protection, such as docking

naval ships, submarines, and other vessels. They also serve as

protective barriers around military ports, providing an added layer

of security and safety.

5. Commercial Shipping: Foam-filled fenders are utilized in

commercial ports and shipping yards to protect cargo vessels,

tankers, and container ships during loading and unloading

operations. They help prevent damage to the vessel's hull and

minimize downtime caused by repairs.

6. Recreational Boating: Marinas and yacht clubs often use

foam-filled fenders to protect recreational boats, yachts, and

sailboats from damage while moored. These fenders provide a gentle

and reliable cushioning effect, ensuring the safety and longevity

of smaller watercraft.

7. Floating Docks and Jetties: Foam-filled fenders are incorporated

into floating docks and jetties to create a resilient and durable

mooring solution. They offer stability, protection, and ease of use

for vessels of varying sizes that need to dock or access these

structures.